|

Creative Research & Fab Lab

Creative research is an experimental, interdiciplinary research approach that links arts, science and culture. Creative research results in applications that fit its users, and is closely related to participatory design, user centered design and tinkering.

Making prototypes plays an important role in creative research. When you are able to quickly materialize your ideas you will be able to challenge, test and evaluate them. On top of that a very powerful and interesting aspect of prototyping is that the act of tinkering stimulates creativity and opens new possibilities. Once you start making things with your hands you start to think in a different way. Off course you will make some mistakes or things turn out different from what you expected, but these mistakes often give you new directions that you would not have found otherwise.

During the fabacademy course assignments I want to explore the role of 'thinking through making' in the creative research process that is practiced at Waag Society. The personal project for the fabacademy will be my test case and at the end of the course I aim to reflect on the following questions:

- How can 'thinking through making' be applied, especially in the early stage of design projects?

- Can 'thinking through making' also help to come up with (more interesting) solutions? Can the hands-on making process also be useful in the design of mainly virtual applications?

- What could be the role of 'thinking through making' in a participatory design process? Which tools, techniques, activities or methodologies would work to design together with others?

In this section I will document interesting things that happen during the making activities of the course, and after the course I will come back to the questions.

From press-fit to snap-fit and back.

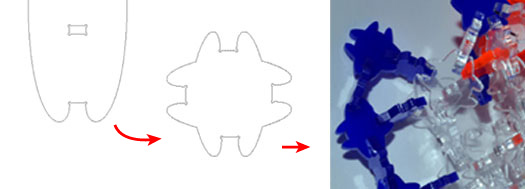

The third assignment of the course was to design a press fit construction - a fastening between two parts which is achieved by friction after the parts are pushed together.

In the fablab we work a lot with acrylic, but since it is very brittle it tends to break as soon as the connections are a bit too tight. So Bas decided to design a more flexible snap-fit construction instead. He made very nice clips that you can squeeze in to click it into another part, and when the snaps release the piece remains in place. With some iterations he ended up with a clip that snap-fits on one end, and accidentaly press-fits on the other end.

It appeared that the end part of his clip perfectly fits around the edge of the acrylic pieces, because the lasercutter causes a ridge along the surface of the cutting plane that causes the desired amount of friction. This brought him to the idea of making a new piece, only consisting of that press-fit end. Interesting that he started the assignment with the aim to avoid press-fit connections, and via snap-fit connections he discovered an improved press-fit connection, that actually looks very pretty as well!

|

Astrids Fab Academy Projects

Astrids Fab Academy Projects